The materials you will need are:

An XLR CableA clamp (to hold your XLR cable)A soldering ironSolderA pair of wire cuttersA knife (not serrated)(Optional) A cable tester

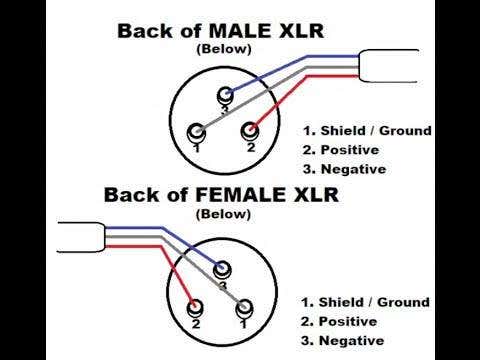

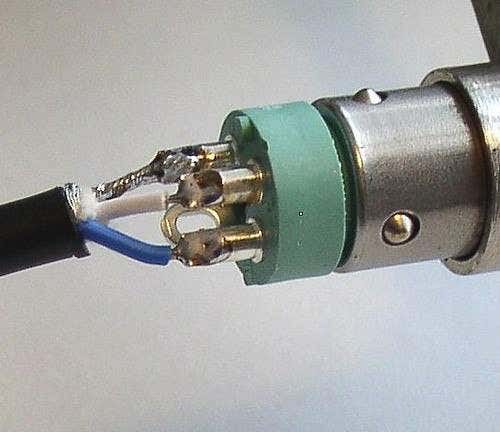

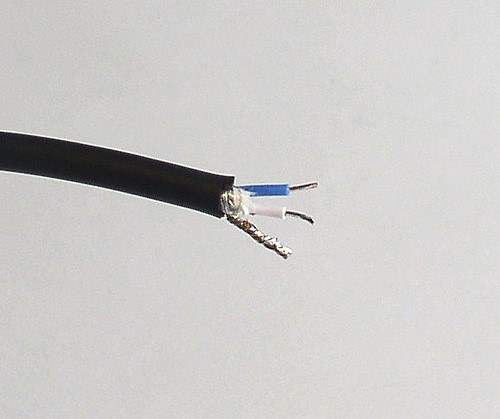

In the picture above, the male end of the XLR cable is on the left and the female end is on the right. It’s important to know the placement of the individual wires within the XLR cable. The picture below will give us this information. Customarily, the Shield/Ground (Copper) wire is always going to be associated with 1, the positively charged (Red or Blue) wire associated with 2 and the negatively charged (White, Blue or Green or Black) wire associated with 3. NOTE: If there’s a white wire inside your cable, your positive end will be red or blue, if there’s a blue wire with no white wire, your positive end will be red. The first thing we’re going to do with our XLR cable is cut both ends of the cable right under the black safeguard, removing the Male and Female ends completely. Unscrew the black safeguard and disassemble the metal shielding until it looks something like this: From here you’re going to firmly clamp down whichever end you’re working on first so you can begin soldering. Here’s what it should look like: From this point, you’re going to take your soldering iron and gently make contact with the bottom of each solder cup until the solder inside the cup heats up enough for you to remove the wires. Clean the remaining solder inside each cup with the tip of your soldering iron. NOTE: the number of the soldering cup will be shown directly above the cup. After this step is completed, it should look something like this: From this point you will need to slide the black safeguard over the wire that we cut earlier. NOTE: this needs to be the first thing that you do before you start stripping the wire and soldering the ends to the male and female ports or else the safeguard will not be able to screw into the metal shielding. After the safeguard is placed over the XLR cable, use your knife and gently press and roll the knife with the wire to strip it, exposing fabric, copper strands, and two wires. From here you will need to completely remove all of the fabric, as we will not need it. The copper strands that are intertwined with the fabric is necessary so DO NOT cut those. After all of the fabric is gone, twist and roll the copper strands together until it forms a larger single strand of copper. Strip no more than 1cm off of the ends of the two smaller wires inside the cable the same way you did for the cable itself. Your cable will look something like this: Before soldering the ends of the wires to their respective cups, we are going to ‘tin’ the ends of the wires and the reservoirs of the cups. The process of ‘tinning’ is very simple; it’s basically just applying fresh solder to the ends of each wire, so when you go to solder them together, it’s much easier for them to fuse. After tinning the ends of the wires, it will look exactly like the picture above, only with shiny metal solder on the ends of the wire. From here we can begin soldering. Refer to the map above to match the ends of the wires to their respective cups. When you’re ready to start soldering, gently place the tip of your wire on top of the solder that’s already in the cup. From there, gently heat the bottom of the cup with the tip of your soldering iron until the solder inside becomes liquid, gently press the end of your wire down into the cup and remove the soldering iron. The tip of the wire should now be fused to the cup. The order of which side you choose does not matter. If you’re soldering the female head first, the grounding wire should be mapped to 1, the positive wire should be mapped to 2 and the negative wire should be mapped to 3. If you’re soldering the male head, the grounding, positive and negative wires are mapped to the same numbers HOWEVER, 1 and 2 will be on opposite sides (Fig. 1). When you finish soldering, you are now ready to assemble the male and female ends, doing the same thing you did in Fig. 2, but in the reverse order. Even though we’re finished, if you’re using the cable for professional audio work or just want to ensure you did everything correctly, I would recommend buying a cable tester to make sure each soldered end has a perfect connection. Here’s the one I use: This cable tester has saved me time and money in the long run and is super easy to use. To see if your cable is working properly, simply plug both ends of your cable into the respective slots on the tester, power it on, switch it to Cable Tester and analyze the red lights on the bottom of the device. The light associated with Pin 1 on the right side should match the respective Pin 1 on the top. Pin 2 (right) should Correspond with Pin 2 (top) and the same with Pin 3. If the cable is working perfectly you should see three red lights illuminated diagonally from the Top Right to the Bottom Left. You’re done! If everything was done correctly, your XLR cable is now as good as new. If you have any questions feel free to ask, I will clarify anything that might have been confusing.